Light Vehicle plate brake testers

Reduce the need for Road Brake testing

To fit the needs of your business or organisation, there are 3 SafeTstop light vehicle plate brake testers to choose from – the Long Track Ultima, Short Track Ultima, and the Brake Tester Eco.

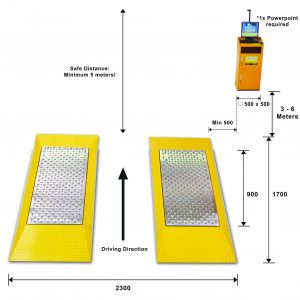

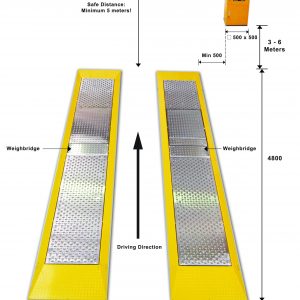

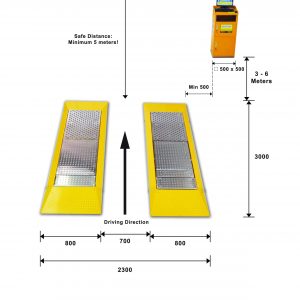

The Long Track Ultima tests all 4 wheels at the same time, while the space-efficient Short Track Ultima model gives the same results, taking a moment more to perform the test. The Brake Tester Eco tests only brake performance.

The testers can sit on your workshop floor (inground models are available) or outdoors (they are not affected by the weather). The test lane is only 50mm high, and can be driven over by light vehicles in any location. SafeTstop turns a useless piece of concrete into a money earner.

In ten seconds, when you drive over the tester, at walking pace, you can provide your customers with a vehicle test, not just a check. The printed report gives detailed measurements of brake force on each individual wheel, brake imbalances and tyre drag. A further test which takes less than one minute will give you suspension rebound measurements, and corner weights and axle weights.

The test provides an accurate, quick and simple report on each vehicle’s brakes and wheel alignment, as well as suspension. The report is printed with date, time and photo proof that the vehicle was tested.

SafeTstop test lanes have been developed in conjunction with regulatory bodies internationally and comply with most government requirements. The test lane is installed without interruption to your work day and staff training is provided, along with follow-up and maintenance.

SEE AN INSTALLATION HERE

Staff Training

Brake and Alignment

Suspension

Weight Scales

SafeTstop takes pride in our product – so we train you and your staff to make sure you get the most from your brake testing equipment. We are available by phone and by email to answer any questions you have working with SafeTstop, and we have a great Partners’ page on Facebook where you can make contact with other SafeTstop workshops and share the amazing things it finds.

Staff training is provided by our staff, face to face in your workshop, within a day or two of installation. We teach you to use the brake tester, the side slip tester, and the weighbridge functions. Your techs will see very quickly how they can use SafeTstop to save time and to reduce the risk in road testing brakes; accidents happen!

Many common wheel, brake and suspension problems can be identified very quickly with a SafeTstop test. Tyre life can be increased for customers by finding tyre drag problems. You and your staff will learn to use SafeTstop to identify overweight vehicles, and where a GVM upgrade is needed, as well as helping customers set up their trailers and identify excessive caravan weights.

We teach you and your staff how simple it is to click through on the computer to perform the tests, and show you the clear and simple printed report. Staff are usually amazed by the easy to understand results and they love to show it to customers, who appreciate the honesty and integrity of your work. If you have found a problem with a customer’s vehicle, the test report can make it clear where the problem was. Many workshops use a “before and after” test report to show customers what has been fixed. We also teach your service advisors to offer the test to customers, and the right way to share with motorists why they need a SafeTstop test and report – proving their vehicle will stop safely in an emergency.

“